Fiori's is my favorite pizza.With the unseasonably warm weather decided to get the car out and get some pizza, with the excuse of trying the thick crust vs. the normal go to

View attachment 234868 View attachment 234869 View attachment 234870 View attachment 234871 View attachment 234872

What did you do to your non-G body project today? [2023]

- Thread starter Wraith

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ever found that you needed a tool that just wasn't to be had? Supposed to be a part number and available but when you go searching, Uh-Uh?

For me tools fall into several categories; Store bought, home made from scratch, and those I term, "adapted" from the fact that they were designed and meant to do one thing but at some point were bent, folded, mutilated, cut, added to or had components removed, in order to make them do something else.

In the following case, I happened to need two pairs of vise grips with a specific throat depth in order to clamp and secure a bracket in place so that it could be checked for location and then sent to the welding bench for installation. When I did score a single pair of grips that looked like they would work, on test run, the clamping pads fell just short of being able to land on the bracket. I do/did have several pairs of the very deep throat clamps but for the job in question they would have hung out way beyond where I wanted them to sit and been a nuisance and a hinderance when the time for the welding came along.

So i came up with these.

For what I needed that would both work for the immediate problem and be versatile enough to use in other situations, I decided that a total throat depth of 8 inches between the clamping pads and pivot point where the fixed and movavble jaws came together would give me a shorter clamp that would be less clumsy and ill-mannered yet still possessing the general versatility that a clamp ought to have.

Not going to bore you with the sturm und drang needed to drill out and remove the factory rivets. (LOL) The process did cost me a drill bit and I suspect that they were both hardened to some degree as well as been set with a press.

with the sturm und drang needed to drill out and remove the factory rivets. (LOL) The process did cost me a drill bit and I suspect that they were both hardened to some degree as well as been set with a press.

Once the rivets were out I could remove the end fingers that held the clamping pads, measure and lay out for how much of the channels I needed to cut off to get them down to the length I needed, introduce them to Dr. Dremel and a micro cut-off wheel, and then re-assemble the fingers back into position.

My first thought was to go with rivets the same as the factory had done but rethought that option given the amount of grief and work it took to remove the old ones, plus the additional pain if I didn't get the holes drilled exactly correct. So I went with plan X, as I had no real reason to make the fingers removable again for any reason, and introduced them to my MIG welder.

Post burn in, I swapped wheels on my dremel and ground a scalloped shoulder for each welded edge to give them a finished? look. Did all this for two vise grips because, who needs an orphan with out a matched second one? With two you can do things, and you can never have too many pairs of vise grips.

And here they are, set in place. All the reach I needed and desired with a little bit more in reserve for other projects to happen in the future that just might need that little more without needing a whole lot more. The fender is now ready to go to the welding bench this weekend.

Nick

For me tools fall into several categories; Store bought, home made from scratch, and those I term, "adapted" from the fact that they were designed and meant to do one thing but at some point were bent, folded, mutilated, cut, added to or had components removed, in order to make them do something else.

In the following case, I happened to need two pairs of vise grips with a specific throat depth in order to clamp and secure a bracket in place so that it could be checked for location and then sent to the welding bench for installation. When I did score a single pair of grips that looked like they would work, on test run, the clamping pads fell just short of being able to land on the bracket. I do/did have several pairs of the very deep throat clamps but for the job in question they would have hung out way beyond where I wanted them to sit and been a nuisance and a hinderance when the time for the welding came along.

So i came up with these.

For what I needed that would both work for the immediate problem and be versatile enough to use in other situations, I decided that a total throat depth of 8 inches between the clamping pads and pivot point where the fixed and movavble jaws came together would give me a shorter clamp that would be less clumsy and ill-mannered yet still possessing the general versatility that a clamp ought to have.

Not going to bore you

Once the rivets were out I could remove the end fingers that held the clamping pads, measure and lay out for how much of the channels I needed to cut off to get them down to the length I needed, introduce them to Dr. Dremel and a micro cut-off wheel, and then re-assemble the fingers back into position.

My first thought was to go with rivets the same as the factory had done but rethought that option given the amount of grief and work it took to remove the old ones, plus the additional pain if I didn't get the holes drilled exactly correct. So I went with plan X, as I had no real reason to make the fingers removable again for any reason, and introduced them to my MIG welder.

Post burn in, I swapped wheels on my dremel and ground a scalloped shoulder for each welded edge to give them a finished? look. Did all this for two vise grips because, who needs an orphan with out a matched second one? With two you can do things, and you can never have too many pairs of vise grips.

And here they are, set in place. All the reach I needed and desired with a little bit more in reserve for other projects to happen in the future that just might need that little more without needing a whole lot more. The fender is now ready to go to the welding bench this weekend.

Nick

Last edited:

one of my non g body projects, my life, took a big upturn tonight.

I proposed, she said yes.

I proposed, she said yes.

in iowa we got a place called northern lights that's pretty damn good.With the unseasonably warm weather decided to get the car out and get some pizza, with the excuse of trying the thick crust vs. the normal go to

View attachment 234868 View attachment 234869 View attachment 234870 View attachment 234871 View attachment 234872

also, as a midwesterner caseys taco pizza gets a mandatory mention.

Congratulations, Pilgrim!one of my non g body projects, my life, took a big upturn tonight.

I proposed, she said yes.

I'm torn between congratulations, and, condolences. (I kid, mostly, after having been together with mine since '09.)one of my non g body projects, my life, took a big upturn tonight.

I proposed, she said yes.

You seem to be on the right track with life moves lately, so, in all seriousness congratulations on this one.

Had

Had my best friend get divorced. Going by a wedding with his then girlfriend yelled “Don’t do it!”. A year later, he married his girlfriend and is still. When you find the right person the decision is right. Congratulations!one of my non g body projects, my life, took a big upturn tonight.

I proposed, she said yes.

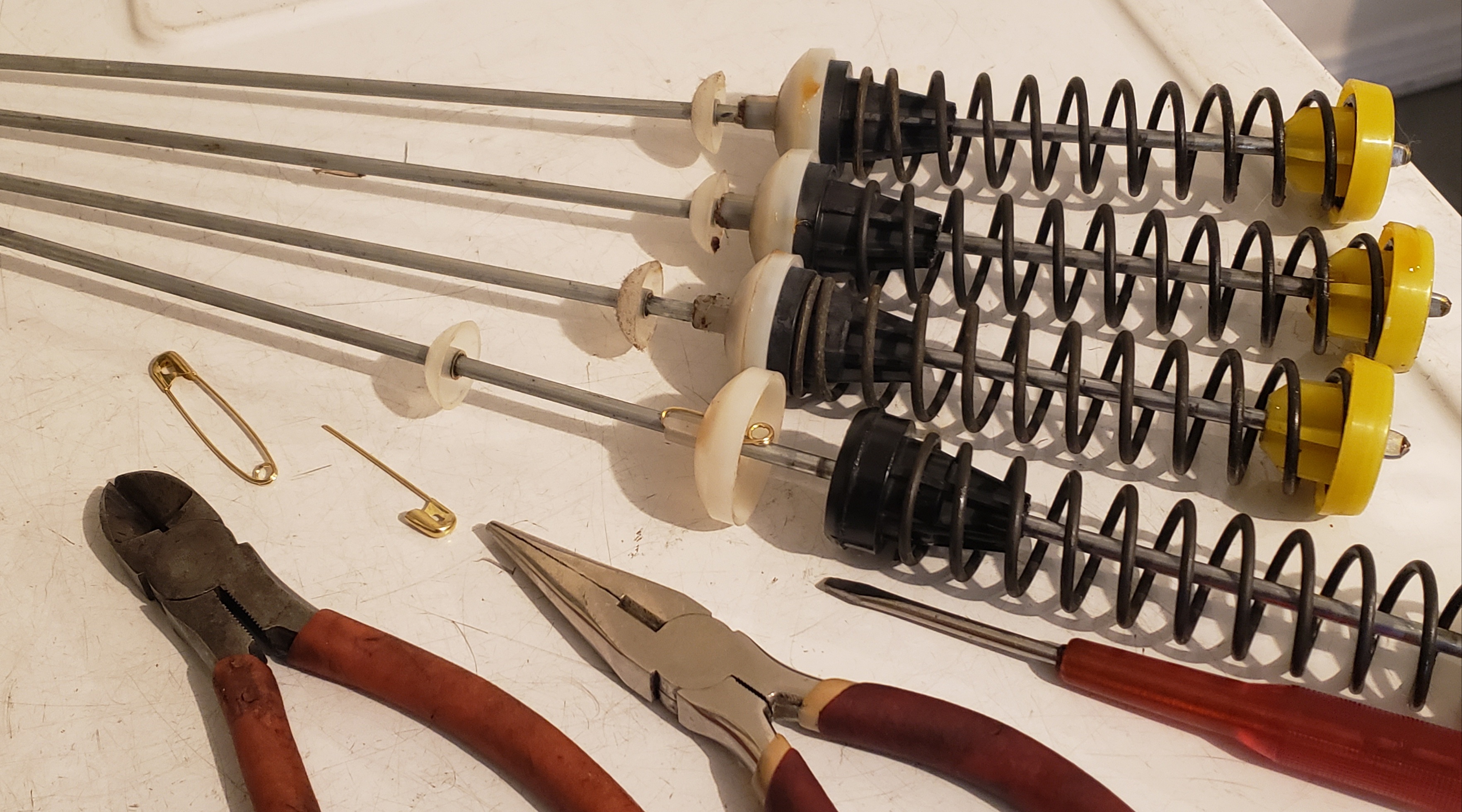

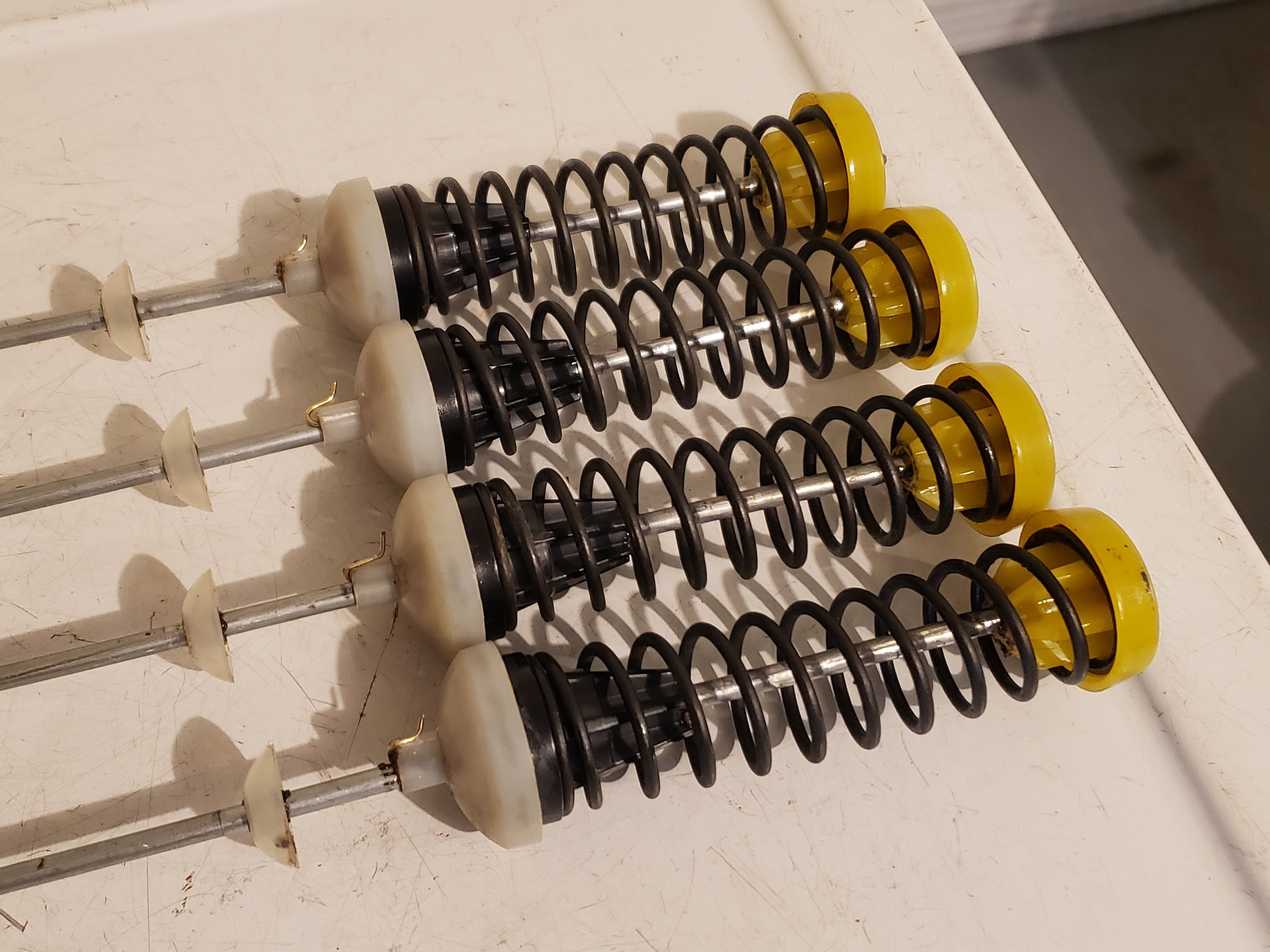

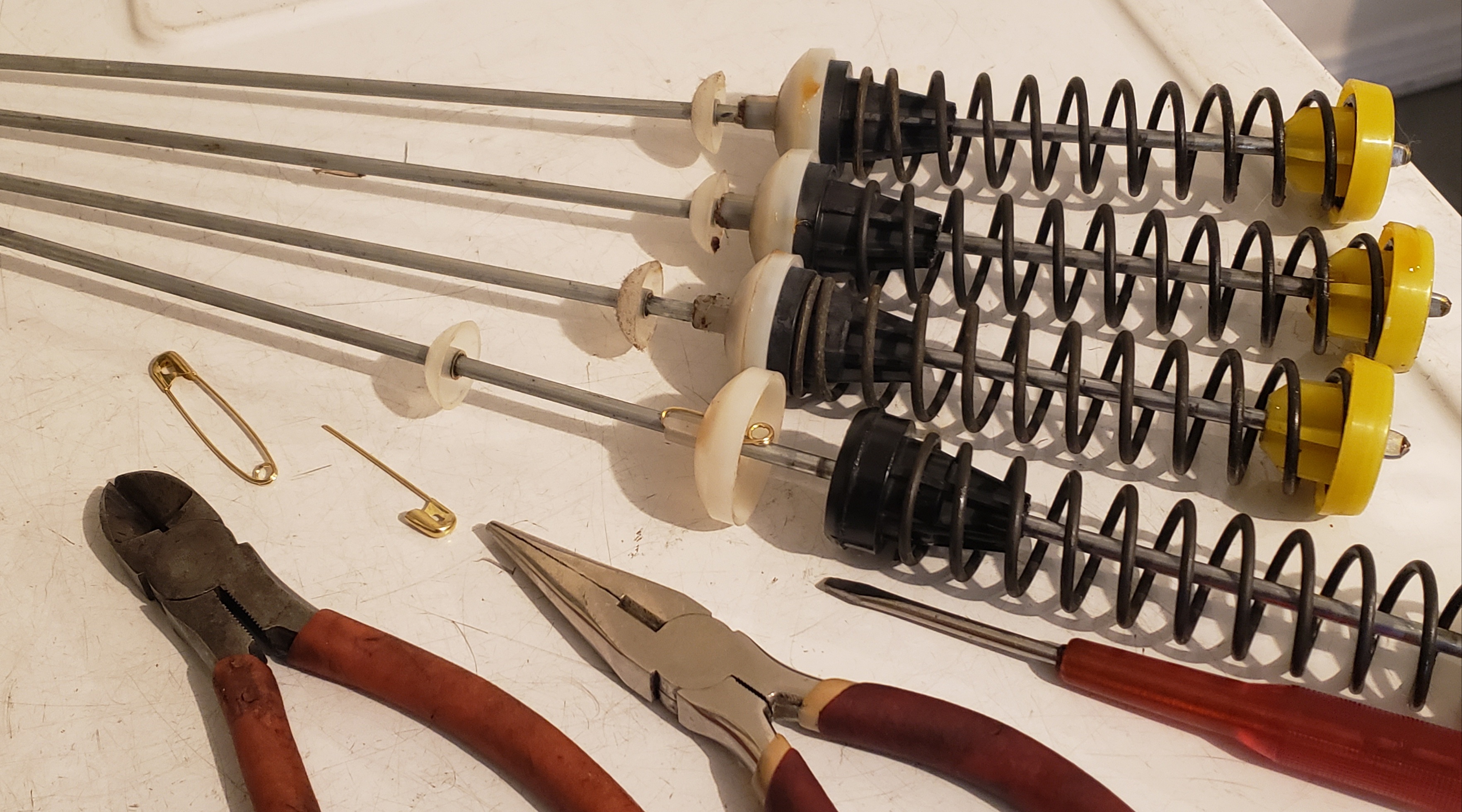

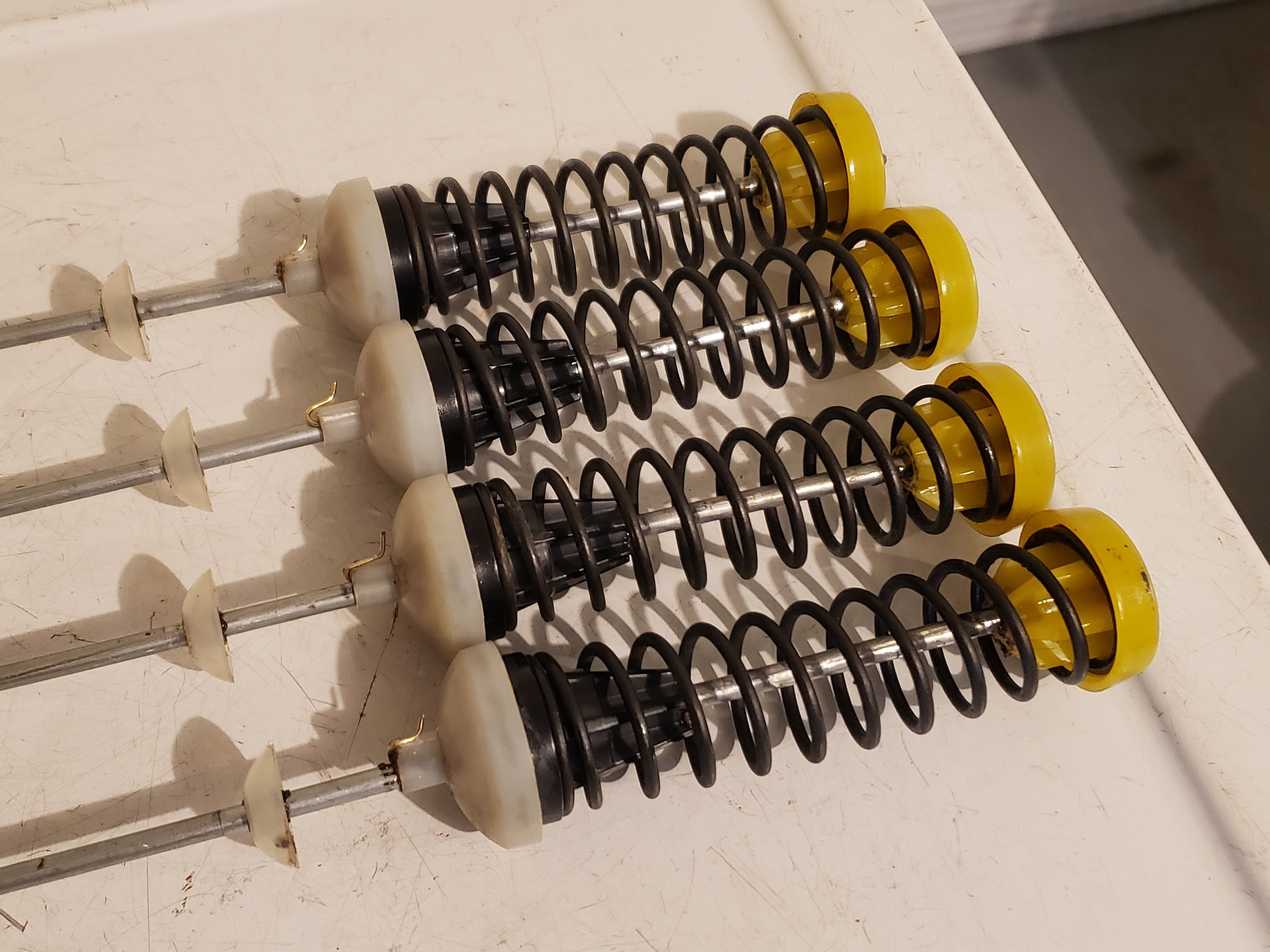

So today's project was fixing the washer. YouTube vid showed me this one. I got this with the dryer both new for $100 from a lady when I was in the process of buying my house. Definitely want to make them last.

There are four suspension rods with springs on them basically to dampen the load shift while you are washing stuff. Inside the upper piece there is a foam bushing that over time loses grip on the rod and therefore causes excess movement. All them loads over the years wore the ole girl out..

The quickest most simplest & cheapest fix was jamming a #3 safety pin through the upper piece of plastic therefore giving metal on metal friction and controlling movement of the spring rebound. That plastic sits in the bottom of the wash drum housing.

Easiest way to get them out was layed on the front, they go out through the bottom. Once they are out it takes like 30 seconds to do one. $3 pack of safety pins genius idea, I'll see how it works this afternoon. So far it's much better and movement is how it should be testing it.

There are four suspension rods with springs on them basically to dampen the load shift while you are washing stuff. Inside the upper piece there is a foam bushing that over time loses grip on the rod and therefore causes excess movement. All them loads over the years wore the ole girl out..

The quickest most simplest & cheapest fix was jamming a #3 safety pin through the upper piece of plastic therefore giving metal on metal friction and controlling movement of the spring rebound. That plastic sits in the bottom of the wash drum housing.

Easiest way to get them out was layed on the front, they go out through the bottom. Once they are out it takes like 30 seconds to do one. $3 pack of safety pins genius idea, I'll see how it works this afternoon. So far it's much better and movement is how it should be testing it.

Last edited:

You m

e you don’t like having it hula dance across the room??🤣🤣So today's project was fixing the washer. YouTube vid showed me this one. I got this with the dryer both new for $100 from a lady when I was in the process of buying my house. Definitely want to make them last.

There are four suspension rods with springs on them basically to dampen the load shift while you are washing stuff. Inside the upper piece there is a foam bushing that over time loses grip on the rod and therefore causes excess movement. All them loads over the years wore the ole girl out..

The quickest most simplest & cheapest fix was jamming a #3 safety pin through the upper piece of plastic therefore giving metal on metal friction and controlling movement of the spring rebound. That plastic sits in the bottom of the wash drum housing.

Easiest way to get them out was layed on the front, they go out through the bottom. Once they are out it takes like 30 seconds to do one. $3 pack of safety pins genius idea, I'll see how it works this afternoon. So far it's much better and movement is how it should be testing it.

View attachment 234931

View attachment 234932

View attachment 234933

Similar threads

- Replies

- 129

- Views

- 12K

- Replies

- 9

- Views

- 676

- Replies

- 1

- Views

- 530

- Replies

- 82

- Views

- 7K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.